Mold solution

模具解决方案

-

高科技HIGH TECHNOLOGY

-

3D DRAWING

Professional design team, proficient in the application of various design software such as: UG, Pro/e, CAD, 3D MAX, Solidworks, CATIA, etc. In the early stages of product design and prototyping, professional design guidance is provided, according to vario -

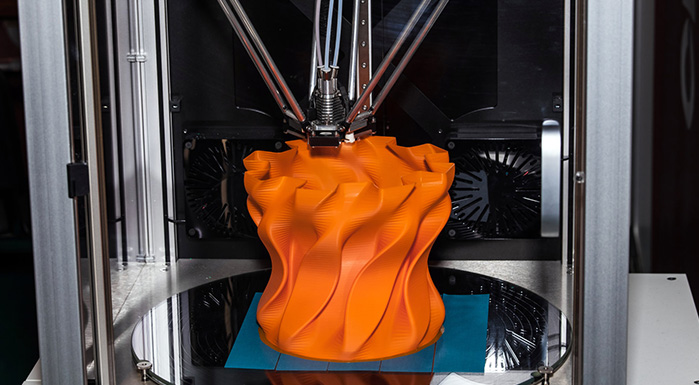

RAPID PROTOTYPING

Provide customers with a professional services at all stages of product development: research and development, rapid prototyping, pre-production, and mass production. Maximize efficiency,save time and cost.

Rapid prototyping is one of the professiona -

CNC

CNC CENTERAdvanced CNC processing technology saves mold manufacturing time, improves efficiency and improves accuracy.CNC millingGet custom milled part for rapid prototyping and production. CNC Milled Prototypes and Production Parts in as Fast as 24 hours.

Highly accurate and repeatable,Suitable for many different kinds of substrates,Low investment in tooling and preparation cCNC turningCNC turning process produces custom prototypes and end-use production parts in as fast as 24 hours. We use a CNC lathe with live tooling so features like axial and radial holes, flats, grooves, and slots can be machined. -

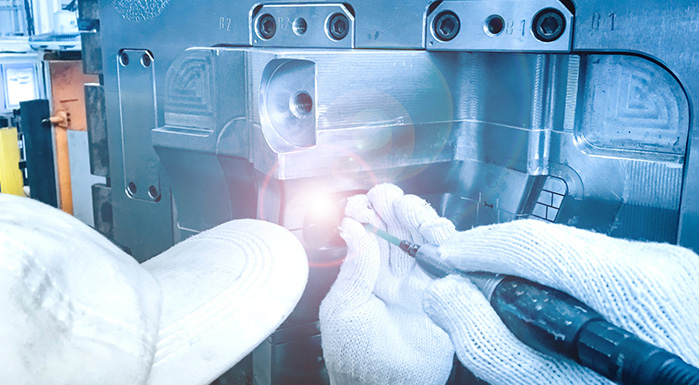

POLISHING

Mold polishing generally uses oil stone, sandpaper, polishing paste, wool wheel, etc. to polish the cavity surface of the mold, so that the working surface of the mold can be as bright as a mirror, which is called mold polishing.

One is to increase t -

CMM

The size and shape data of various measured objects are obtained and returned in a series of ways, which realizes the efficient and high-precision measurement and evaluation of basic geometric elements, and solves the measurement problem of complex shape surface contour size. Therefore, it has unique advantages in measurement:

1. It can measure almost all parts, including test pieces in the process of product development and improvement, and can also be inspected at any time, which is fast and low cost< br> 2. It can evaluate the condition of the machine tool, including the accuracy, feed status or control of the machine tool< br> 3. The measuring capability of CMM provides the possibility for users to adopt new technologies in design, processing and materials< br> 4. The measurement results are more reliable, because the measurement results largely exclude human influence< br> 5. The reliable quality assurance of the CMM even becomes a necessary prerequisite for supply and is written into the contract.

-

-

高效率High efficiency

-

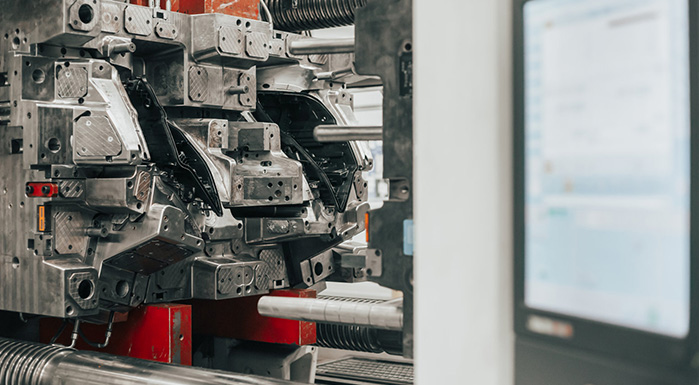

EDM MACHINE

It is used to process various complex and precise work pieces, such as punches, dies, punch-and-concave dies, fixing plates, stripping plates, etc. of punching dies, forming tools, templates, and metal electrodes for EDM processing. A variety of micro-hol -

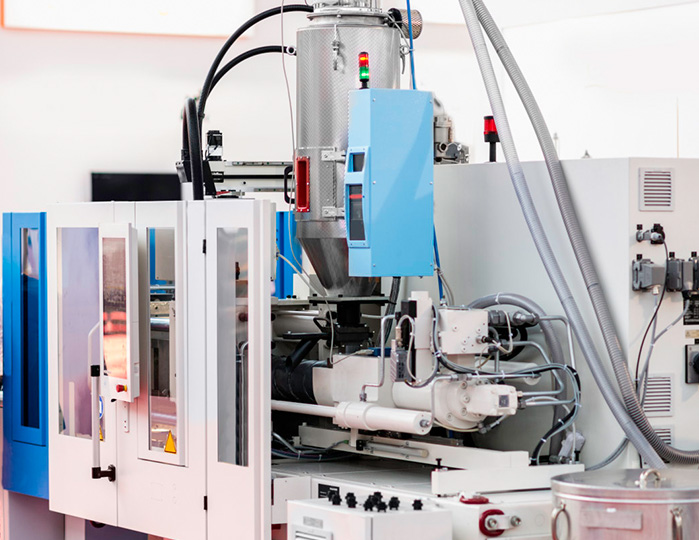

PLASTIC INJECTION

YUMIS provides complete manufacturing solutions covering all aspects of raw material verification, tool manufacturing, part manufacturing, finishing and final inspection. Designer teams and production teams are dedicated to providing you with the highest -

PLASTIC PRODUCING

The YUMIS team focuses on high-quality custom injection molding and mold making. Injection molding is currently the most commonly used method of manufacturing plastic parts in the industry, especially when it comes to high-volume production. The YUMIS tea -

INSPECTION

YUMIS has its own professional quality inspection team, which strictly inspects the quality of molds or injection molding products in accordance with industry standards and customer standards,to provide customers with good products. While ensuring efficie

-